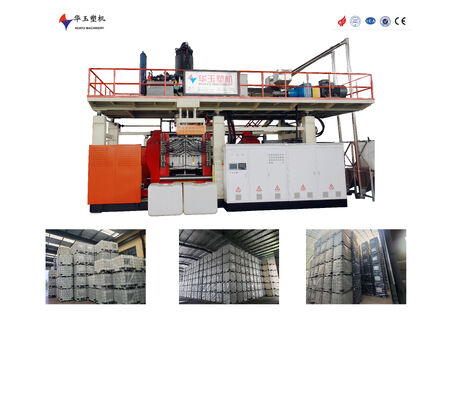

آلة IBC أوتوماتيكية تتضمن لوحة 1700 1800 مم مصممة لحلول تعبئة وتداول الحاويات السائبة

| البعد الآلة | 12*7*7M | نظام التبريد | تبريد المياه |

|---|---|---|---|

| الجهد االكهربى | يعتمد على | مستوى الأتمتة | نصف أوتوماتيكي / أوتوماتيكي بالكامل |

| متانة | ممتاز | معالجة البلاستيك | البولي إثيلين عالي الكثافة |

| دورة الدراجات | 2 دقيقة | نوع الطارد | المسمار واحد |

| إبراز | آلة IBC أوتوماتيكية مع لوحة,آلة نفخ قوالب خزان IBC 1700 مم,آلة تعبئة الحاويات السائبة 1800 مم,IBC tank blow molding machine 1700MM,bulk container filling machine 1800MM |

||

![]()

وصف المنتج:

آلة صناعة IBC هي أحدث قطعة من المعدات المصممة خصيصًا لإنتاج حاويات السائل الواسعة الجودة والفعالة (حاويات IBC).مع تكنولوجيا مبتكرة وبناء قوي، هذه آلة صناعة الصب يضمن أداء متفوق، مما يجعلها خيارا مثاليا للمصنعين الذين يتطلعون إلى إنتاج خزانات IBC دائمة وموثوقة لمختلف التطبيقات الصناعية.

يبلغ طولها 12 متراً، وعرضها 7 متراً، وارتفاعها 7 متراً، وتحتل آلة IBC مساحة متوازنة بين القدرة الإنتاجية وتحسين مساحة المصنع.حجمها الكبير يسمح للتعامل مع القوالب الكبيرة ودورات الإنتاج الكبيرة، وهو أمر ضروري لتلبية المتطلبات الصعبة لحلول التعبئة والتغليف الصناعية الحديثة.تصميم آلة صناعة الطلاء يؤكد سهولة التشغيل والصيانةلضمان الحد الأدنى من وقت التوقف وأقصى قدر من الإنتاجية.

المتانة هي سمة مميزة لهذه آلة صناعة الصبالجهاز يقدم موثوقية ممتازة على المدى الطويلتترجم هذه المتانة إلى انخفاض تكاليف الصيانة وطول عمر الخدمة، مما يسمح للمصنعين بالحفاظ على إنتاج ثابت دون انقطاع متكرر.الهيكل القوي والمكونات عالية الجودة تضمن أن يتم تشكيل القوالب خزان IBC بدقة وتوحيد، مما يؤدي إلى منتجات تلبي معايير الصناعة الصارمة.

يتم تجهيز الجهاز بجهاز طحن مقطوع واحد ، وهو عنصر حاسم لعملية صناعة الصب. يذوب جهاز طحن مقطوع واحد بفعالية ويتجانس المواد البلاستيكية ،توفير تدفق ثابت ويمكن التحكم به إلى القالبهذا يؤدي إلى خزانات IBC ذات سمك جدار موحد وسلامة هيكلية متفوقة.تمكين المصنعين من تخصيص عملية الإنتاج وفقًا للمتطلبات المحددة لأحجام المواد المختلفة.

كآلة جديدة، تتضمن آلة صناعة صناعة IBC أحدث التطورات التكنولوجية في تكنولوجيا صناعة الصب. وهذا يضمن زيادة كفاءة الطاقة،وواجهات سهلة الاستخدام تبسط العمليةالحالة الجديدة للآلة تضمن أن جميع الأجزاء والمكونات في مستويات أدائها المثلى ، مما يوفر دورات إنتاج موثوقة ومتواصلة.

واحدة من الميزات الفريدة لهذه الآلة IBC هي متطلبات الجهد قابلة للتكيف.يسمح بالاندماج السلس في بيئات التصنيع المختلفة في جميع أنحاء العالمهذه المرونة تجعل آلة صناعة الصب مناسبة لمختلف الإعدادات الصناعية ، سواء في المناطق التي تحتوي على إمدادات الجهد القياسية أو تلك التي تتطلب تكوينات كهربائية مخصصة.

باختصار ، تبرز آلة IBC Tank Blow Molding كحل فعال للغاية ودائم لإنتاج خزانات IBC عالية الجودة.مزيج من ملامح متينة ممتازة ومضخة مضغوطة واحدة موثوقة، يضمن أن الشركات المصنعة يمكن أن تلبي الطلب المتزايد على حاويات السلعة المتوسطة القوية والمتنوعة.أنها توفر مزيج مثالي من الابتكار، والموثوقية، وتخصيص لعمليات صناعة الصب الحديثة.

سواء كنت تقوم بتوسيع قدراتك الإنتاجية أو إنشاء خط تصنيع جديد، هذه آلة صب الصب يمثل استثمار قيم.انها لا تدعم فقط إنتاج خزانات IBC المتقدمة التي تتوافق مع معايير الصناعة ولكن أيضا تحسين الكفاءة التشغيلية العامةتم تصميم آلة IBC لتقديم جودة ثابتة ، وتعظيم الإنتاج ، وتقديم خدمة طويلة الأجل ، مما يجعلها أصل لا غنى عنه في مجال تصنيع الحاويات الصناعية.

الخصائص:

- اسم المنتج: آلة IBC للصناعة

- الجهد: يعتمد على متطلبات العميل

- البلاستيك المعالج: HDPE

- نظام التبريد: تبريد المياه للسيطرة الفعالة على درجة الحرارة

- وقت الدورة: دقيقتين لإنتاج سريع

- متانة: ممتازة، وضمان أداء طويل الأمد

- آلة صناعة الصب عالية الجودة مصممة لإنتاج خزانات IBC

- آلة صناعة IBC موثوقة مناسبة لتطبيقات صناعية مختلفة

- تقنية آلة IBC المتقدمة لتحقيق دقة وفعالية عالية في التشكيل

المعلمات التقنية:

| إمدادات الطاقة | 380 فولت / 50 هرتز |

| مقاس الجهاز | 12*7*7m |

| حجم الصفيحة | 1700*1800ملم |

| الحالة | جديد |

| مستوى الأتمتة | نصف أوتوماتيكية / أوتوماتيكية بالكامل |

| المدى الطويل | ممتاز |

| نوع المخرج | مسدس واحد |

| وقت الدورة | دقيقتان |

التطبيقات:

آلة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صهذه الآلة شبه التلقائية أو الكاملة التلقائية مثالية لمختلف التطبيقات الصناعية حيث حاويات السلع الكبيرة المتوسطة القوية والقوية ضروريةمع طاحونة خرطوشة واحدة ونظام تبريد مياه، يضمن HYBM-IBC جودة الإنتاج المتسقة وأداء التبريد الأمثل،مما يجعلها مناسبة لبيئات التصنيع على نطاق واسع.

هذه آلة صناعة الصب يجد تطبيق واسع في الصناعات مثل المعالجة الكيميائية، الزراعة، الغذاء والمشروبات، الصيدلة، والخدمات اللوجستية،عندما يكون تخزين السوائل والمواد السائبة ونقلها آمنين أمرًا حاسمًاالخزانات IBC التي تنتجها نموذج HYBM-IBC مثالية لتخزين المواد الكيميائية والماء والزيوت والسوائل الأخرى ، وتقدم مقاومة ممتازة ومتانة.بفضل مستويات التشغيل شبه التلقائية أو التلقائية بالكامل، هذه الآلة تلبي متطلبات الشركات التي تتطلب المرونة والإنتاجية العالية.

المصنعة في الصين ومعتمدة بمعايير CE و ISO9001 و SGS ، تضمن آلة صناعة صناعة الصب الصنف HYBM-IBC الامتثال للمتطلبات الدولية للجودة والسلامة.أبعاد الجهاز الكبيرة من 12 × 7 × 7 متر وإمدادات الطاقة من 380 فولت / 50 هرتز تجعلها مناسبة للتركيب في بيئات مصنع واسعةيتم تخصيص حزمة الجهاز وفقًا لاحتياجات العملاء ، مما يضمن التسليم الآمن. مع قدرة إمداد 40 مجموعة سنويًا ووقت التسليم من 4-6 أشهر ،يمكن للعملاء تخطيط جداول المشتريات بشكل فعال.

آلة صناعة الصب IBC هي أيضا مثالية للشركات التي تسعى لتوسيع خطوط منتجاتها أو تحسين كفاءة الإنتاج، لأنها تدعم الحد الأدنى لكمية الطلب من مجموعة واحدة فقط،مع تسعير متاح من خلال التفاوضشروط الدفع مثل TT أو L / C توفر خيارات مالية مرنة للمشترين الدوليين.آلة صناعة الصب هايو بي إم-آي بي سي هي الحل المثالي للشركات التي تهدف إلى إنتاج عالية الجودة، مخازن IBC دائمة الدوام من خلال تقنية صناعة الصب النفخة الموثوق بها.

التخصيص:

مقدمة آلة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعةهذا النموذج الجديد يفتخر بالمتانة الممتازة ويعالج البلاستيك HDPE لضمان خزانات IBC قوية وموثوقة لمختلف التطبيقات الصناعية.

مع شهادة CE و ISO9001 و SGS ، يضمن HYBM-IBC الجودة العليا والامتثال للمعايير الدولية.توفر مساحة واسعة لإنتاج فعالتعمل الآلة على فولتاج يعتمد على متطلبات العميل، مما يضمن المرونة للأسواق المختلفة.

نحن نقدم الحد الأدنى لكمية الطلب من مجموعة واحدة فقط، مع الأسعار مفتوحة للتفاوض لتلبية الاحتياجات الخاصة بك.يتم تخصيص تفاصيل التعبئة والتغليف وفقًا لمتطلبات العملاء لضمان التسليم الآمن لجهاز صناعة الصب IBC الخاص بك.

وقت التسليم لـ Huayu IBC عادة ما يكون 4-6 أشهر ، مدعومة بقدرة التوريد من 40 مجموعة في السنة. شروط الدفع تشمل TT أو L / C ،توفير خيارات مريحة للمشترين الدوليين.

اختر آلة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صناعة صنا

الدعم والخدمات:

لقد تم تصميم آلة صناعة الصب IBC لتوفر إنتاج فعال وموثوق به من حاويات السلع الفائقة ذات جودة عاليةفريقنا من الخبراء متاح لمساعدتك في التثبيت، التشغيل، وإصلاح الأخطاء، والصيانة لضمان أداء أفضل للجهاز.

نحن نقدم خدمات شاملة بما في ذلك التدريب في الموقع، وبرامج الصيانة الوقائية، وإمدادات قطع الغيار في الوقت المناسب لتقليل وقت التوقف وتطويل عمر معداتك.دعمنا يشمل أيضا تحديثات البرمجيات واستشارات تحسين العمليات لمساعدتك على تحقيق أقصى قدر من الإنتاجية والفعالية من حيث التكلفة.

سواء كنت بحاجة للمساعدة أثناء الإعداد الأولي أو الدعم التشغيلي المستمرفريق الخدمات التقنية المخصص لدينا ملتزم بتقديم حلول سريعة ومهنية مصممة خصيصا لاحتياجاتك الخاصة.